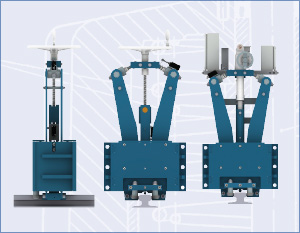

Rail Clamp Systems

- High durability

- Position of clamp remains unchanged in case of power failure (fail-safe)

KoRo IBS Rail Clamp electro-hydraulical

Rail Clamp electro-hydraulical

(PDF, 2.32 MB)

Operation:

- Closing through spring force

- Adjustable throttle (time delay 3 - 120 sec.)

- Opening through hydro-cylinder und hydro-aggregate incl. emergency hand-pump in case of power loss

- With power loss the rail clamp closes automatically (fail save)

- Holding force per rail clamp with μ = 0.25 or μ = 0.4ZWA

Special Features:

- Automatic rail clamp; horizontal movement ± 25 mm and vertical movement ± 20 mm. Two idlers inside the clamp housing guide the rail clamp on the rail

- No loss of clamping force resulting from jaw wear because reduced spring force is compensated by increasing the toggle lever transmission

- Limit switch controls the position of rail clamps "clamp open", "clamp closed", "jaw wear"

- Pressure switch in hydro aggregate redundant to mechanical limit switch at the clamp car

- Holding force per rail clamp with μ = 0.25 or μ = 0.4 according to DIN 15019 Part 1

- Exchangeable clamping jaws

- Emergency hand-pump in case of power loss

- Electro-installation complete to terminal box on the clamp housing

- Hydraulic system, hydro-aggregate and hydro-cylinder are ready for operation, hydraulic oil is included

- Clamp housing idlers hardened

- ZWA car support rail VHS for maintenance free operation of the rail clamp is included

- Aluminium cover is protected from environmental influence when it is completely closed. On demand the sides of the cover can be turned around, so that 2 big vertical openings develop

- 160 μm paint with four layers standard

- Rapid interchangeability of the units , like hydro-cylinder and hydro-aggregate

Download (PDF files)

To view the PDF files you need Adobe Reader, which can be downloaded from the Adobe website.

If you need further information or have questions, we are happy to assist you. > Contact